Installation Method

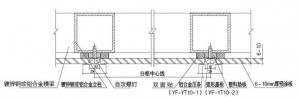

(一) Layering Type

A delicate and highly elongated adornment line, give a person a higher longer visual sense, lively line concise artistic conception.

Features:

1. The prefabricated installation, do homework, modular, convenient and quick.

2. The solid structure, removable, can repair.

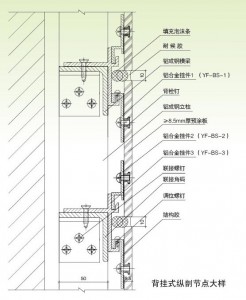

(二)The Back Hanging

Appearance is concise, lively.

Features:

1. The structure is stable, safe

2. Easy installation and adjustment

2. The reserved crack-cleaning constructive ventilating curtain wall system

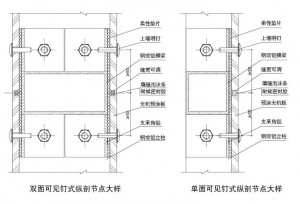

(三) The Visible Order Type

Safe and reliable, convenient and quick installation, the economy is good, adornment nail and plate color match reveal the beauty of the rugged

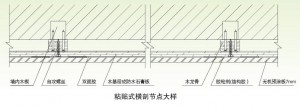

(四) Embellishment (plus anchor)

Easy installation, economy, takes up less space

Fastening methods: structural adhesive, double-sided adhesive sticky tape

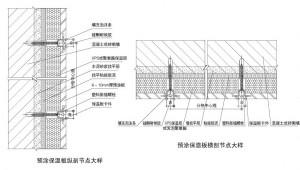

(五)Card Type (insulation system)

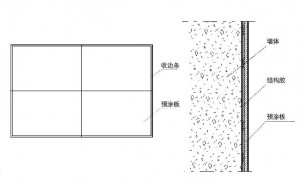

(6) Closed

Technical parameter:

| Testing terms | Testing reference | Testing conclusion | |||

| Thickness(mm) | GB/T 17748-1999 | 4-12mm | |||

| Dimension(mm) | |||||

| Dimension Deviation | Length(mm) | ≤2 | -1 | ||

| Thickness(mm) | ≤0.05 | -0.5 | |||

| Diagonal difference(mm) | ≤2 | 2 | |||

| Fringe nonstraightness(mm/m) | ≤2 | 1 | |||

| Warpage(mm) | ≤5 | 2 | |||

| Density(g/cm3) | ≥1.6 | 1.6-1.7 | |||

| Resistance to change of temperature | GB/T 17748-1999 | Had no effect on | |||

| Dry shrinkage rate | JC/T671-1997 | 0.07 | |||

| Water absorption(%) | ≤5 | 1.79 | |||

| Water impermeability | GB/T019-1999 | Without dripping in the bottom | |||

| Coefficient of thermal expansion | GB/T17748-1999 | 8*10-6 | |||

| Thermal conductivity | ≤0.5W/mk | 0.3W/mk | |||

| Elastic modulus | ≥8000N/mm2 | 9000N/mm2 | |||

| Drawing bolt force(N/mm) | Normal | JC/T564-1994 | 190 | ||

| Warm | 234.9 | ||||

| Incombustibility | GB545640-1985 | A级 | |||

| Flexural strength(Mpa) | GB/T7019-1997 | 38.8 | |||

| Resistance to shock strength(KJ/m2) | GB/T25741-1995 | 4.74 | |||

| Frost resistance | Without dusting or peering off after 15times of freezing-melting circulation | Without failure phenomena of dusting or pearing off | |||

| Color | Solid/meta;/pearlized color | ||||

| 60℃ Iuster | GB/T9754-1988 | Low/mid/high glazing | |||

| Hardness | GB/T6739-1996 | 2H-4H | |||

| Resistance to change if temperature | GB/T17748-1999 | -40-150℃,Unchanged | |||

| Resistance to solvent | GB/T17748-1999 | Butanone>not expose the basicboard when soaking in butanone 100times | |||

| Acid resistant | GB/Y17748-1999 | Had no effect on | |||

| 10%HCL24h | |||||

| 10% sulfuric acid 24h | |||||

| Alkali resistant | GB/T17748-1999 10%NaOH 24h | Had no effect on | |||

| Resistance to detergent | 3% 40℃ | Had no effect on | |||

| Weather resistance | GB/T16259-1996 | Luster loss than 30% within 3000 hours, color changes not over than 5NBS | |||

| Insolation outdoors | ASTM D-2244-85 | Luster loss than 50% on outside of 10 years, color changes not over than 5NBS | |||