What is External Wall Insulation (EWI)?

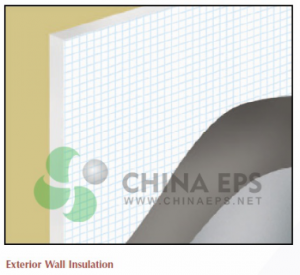

External Wall Insulation (EWI) is a composite cladding system comprised of suitable insulation and waterproof coating which isapplied to all the external walls of a building. The application of EWI reduces heating bills, and consequently, carbon emmisios also.

External Wall Insulation (EWI) is the most efficient way to insulate an exsisting building. FACT!

It uses the fabric of the building like a storage radiator. Because the heat can no longer escape through the outer layer of insulation, it is reflected back into the living areas, creating a constant warm home. That’s why Polar Bears have their insulationon the outside!

With up to 40% heat lost through external walls, EWI can help reduce your heating bills by up to 40%. It can also reduce your carbon footprint by cutting your CO2 emmissions by up to 2.5 tonnes per year.

How is External Wall Insulation (EWI) Applied?

Step 1

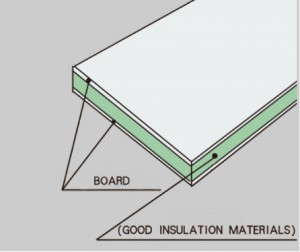

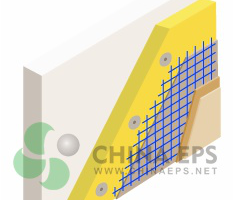

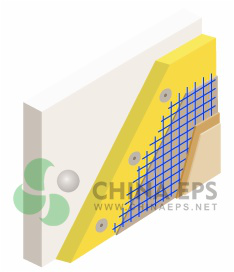

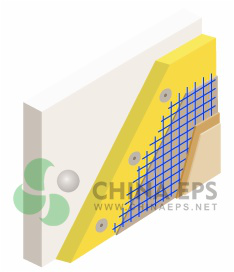

The required type and size of insulation is mechanically and adhesively fixed to all external walls. This creates an insulation envelope that prevents heat loss and cold bridging, which can occur using other types of insulation, e.g. cavity fill.

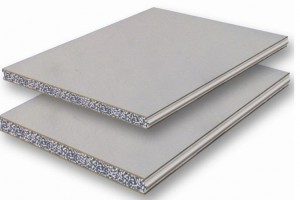

EPS Borads is one of 3 main types of Insulation boards used in EWI systems. It is mechanically and adhesively fixed.

Step 2

An alkali-resistant open-weave fibre mesh is embedded onto the insulation board using a polymer modified cement basecoat.

This provides both impact resistance and tensile strength.

Step 3

A coloured primer is applied (by roller, brush or spray) to the basecoat when fully dry. (Drying takes approximately 24 hours.) This aids adhesion/ water resistance, and also improves the colour uniformity on the final finish.

Step 4

A low maintenance coloured and textured acrylic render finish is then applied (troweled or sprayed). There is an extensive pallet of colours and textures to choose from. The final result is a durable low maintenance finish that will only need hosing down to clean every 3 to 5 years . (As the finish has a 1% fade rate in a 10 year period, accent colours might fade slightly.)